Company

Industrias Químicas Tamar,

projection of the future

More than 20 years betting on a constant evolution - Thanks to our work, Tamar has managed to position itself as one of the most important manufacturers of chemical products. We continue betting on quality and service together with competitiveness, very present objectives to guarantee the future.

José Martí Silvestre

CEO

QUALITY PRODUCTS

We take maximum care of the quality of our products. We have our own laboratory and quality department to ensure that the products meet both of the market and legislative requirements.

ATTENTION AND SERVICE

We know that our clients are the basis of our success. That is why we pay a lot of attention to the treatment and service we offer. We try to avoid any type of incident and if it happens, resolve it as soon as possible. We have an excellent logistics department and customer service.

INTERNATIONAL PROJECTION

After consolidating in the national market, Tamar has begun to expand by opening new international markets. An excellent location allows us to export our products efficiently and competitively anywhere in the world.

HUMAN TEAM

For a large business project to work, you need to have a good work team. Tamar is formed by great professionals that make possible the fulfillment of the objectives and the projection of the company.

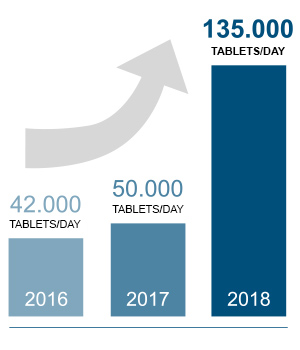

LINE OF TABLETS

After automating in 2017 the process of feeding the cube of tablets and improving the process of loading of mixtures, a new rotary line of high productive capacity is introduced in 2018. The manufacture of daily tablets goes from 42,000 in 2016 to the current 135,000.

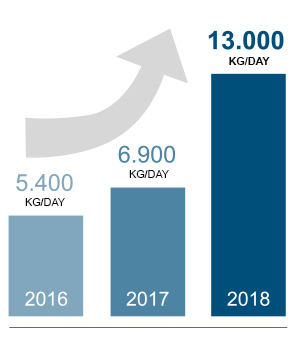

LINE OF GRAINS AND SOLIDS

The filling and weighing process is improved in 2017 and a line ending is added. In 2018, the entire process is automated, from producing 5,400 kg to 13,000 kg daily.

LIQUID LINE

In 2017, the filling capacity is increased and a line end is added. In 2018, a new high-speed liquid plant was moved and installed, going from producing 6,700 liters / day to 14,000.